Can human–robot collaboration tackle manual handling challenges?

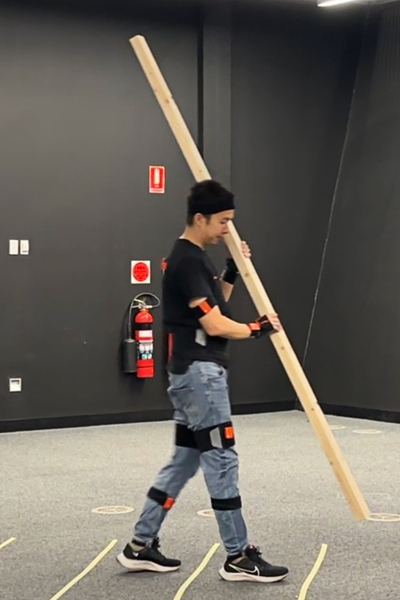

Australian engineers have trialled a human–robot collaboration system designed to make construction faster, safer and less physically demanding.

Setting out to tackle a key challenge in construction robotics, a recent paper — published in Automation in Construction — sets out a human–robot collaboration system trialled by researchers from Monash University’s Department of Civil and Environmental Engineering. The trial explored not only which tasks robots should handle and which should remain with human workers, but also incorporated human fatigue into the planning process.

The team, under the supervision of Dr Yihai Fang, simulated humans and robots assembling a timber floor frame for a three-bedroom unit, breaking the work into 71 tasks. Task completion time, productivity and physical fatigue were measured and, using real data from Monash’s UR10e robotic arm and MiR100 mobile robot, carefully allocating tasks and sequencing workflows was found to make construction more efficient, while easing physical demands on human workers.

“Collaborating with robots in construction is no longer a distant vision — it’s rapidly becoming a reality,” Fang said. “Faced with ongoing challenges such as low productivity, labour shortages and high injury rates, the industry must embrace innovation by integrating automation and advanced robotic technologies.”

|

|

According to study first-author Dr Will Wang, job sites could be transformed by making the move towards automation and robotics. “The simulations really show how robots could take the strain off workers — they can handle the heavy lifting and repetitive jobs, while humans focus on planning, problem-solving and making sure everything fits perfectly,” Wang said.

“It’s exciting to see how off-site prefabrication and smart onsite collaboration could actually make construction safer and faster for workers.” Wang added: “Figuring out which tasks should be done by humans and which by robots is a major hurdle. Our study lays the groundwork for a safer, more efficient and human-focused approach to integrating robotics into structural assembly.”

As to future research directions, the team is now testing augmented reality guidance — to demonstrate how humans and machines could work together seamlessly. As part of this research, participants wear AR headsets that act like ‘smart eyes’, showing them the best route between storage and work zones and previewing the robots’ movements — something that is designed to helps workers coordinate with robots, speed up tasks, reduce mistakes and stay safer on site.

The paper on the human–robot collaboration system was published open access and you can read it at doi.org/10.1016/j.autcon.2025.106464.

What is the work-related impact of long-term back problems?

Australian researchers have set out to project the work-related impact of long-term back problems...

Construction materials company extends road safety program

Australia's largest vertically integrated construction materials company has extended its...

AI platform streamlines ergonomic and hazard assessments

A natural health products company integrated an AI platform into their safety processes,...