Early detection of surface mine subsidence

Malfunctioning machinery may be a warning sign for subsidence issues on mine sites, according to ground engineering specialist Mainmark. Often overlooked yet easy to address, subsidence can cause costly downtime and production bottlenecks if not identified early.

“Minor variances in ground level caused by subsidence can have a significant and costly impact on the smooth running of mine site machinery,” said Tom Bailey from Mainmark. “Machinery malfunction is often attributed to poor-quality or shoddy equipment when, in fact, the problem may be a result of misaligned parts caused by ground subsidence.”

Subsidence refers to the gradual caving in or sinking of an area of land. The most common causes of subsidence on a surface mine include drainage issues (caused by broken pipework or gradient that inhibits surface water run-off), poor compacted fill and mechanical vibrations which wear down the ground.

Subsidence causes machinery parts to change configuration, placing unnecessary stress on equipment and conveyor belts. Early signs of machinery misalignment include:

- unusual noise from the machinery

- abnormal wear and tear, particularly on conveyor belts due to additional impact

- excessive wear on machinery paths and bases, as a result of excessive vibrations that cause them to sink.

“Sustained over a period of time, this may cause the equipment to break down. The result is expensive repair and maintenance, decreased productivity and, in some cases, safety risks,” said Bailey.

Addressing subsidence before machinery fails is recommended for minimising the costs of downtime and, with modern ground engineering techniques, can be easier and quicker than many anticipate.

“Resin injection technology, such as Mainmark’s Uretek solution, is a proven, convenient, efficient and cost-effective alternative to traditional ground support techniques, such as underpinning. This method injects resin into fractured, broken or unstable rock and soils at high pressure to consolidate and restabilise the ground,” said Bailey.

Fast-set resin injection can be applied in situ with minimal interruption to site operations. Depending on the scope of work, a project may be completed in a matter of days and performed outside of programmed maintenance shutdown periods, allowing for flexible scheduling.

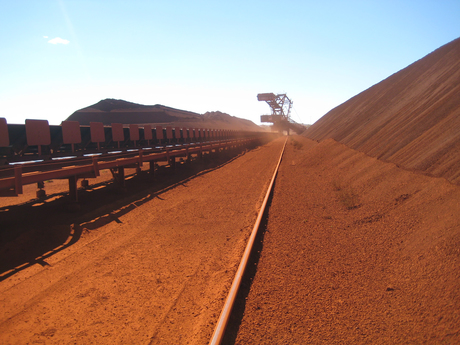

Relevelling a stacker crane rail

A Queensland coal mine recently appointed Mainmark to relevel a rail-mounted reclaimer. One of the rail’s footing beams had sunk, causing the crane to malfunction and limiting access to coal stocks. Due to leaking water pipes, the rail footing deflected under load, causing the slab joint to sink. Mainmark’s expanding structural resin, Uretek, was injected under the rail footing beam to resupport and relevel it. The engineered resins combine chemically on entering the ground. The process is monitored by laser level to maintain control and deliver a precise result.

In just three days, Mainmark had relevelled and resupported the crane rail and supporting beam, facilitating access to a significant stock of export coal.

Mainmark said its methods strengthen and stabilise the ground with no negative impact on the environment. These specialist techniques deliver optimum results and projects can often be completed while site operations continue. Non-invasive methods mean that no excavation is required, minimising mess and hazards.

Vehicle-based thermal camera has pedestrian safety in its sights

A thermal longwave infrared camera has been developed to improve automatic emergency braking and...

Radio-based capabilities partner with advanced telematics to drive safety

A fleet safety partnership has been announced that combines radio-based safety features with...

Rock lobster processor and exporter finds driver safety partner

A transport technology solutions provider has announced a new contract to enhance safety with...